JHCI-102C-UD JECO UV curing machine is designed for each UV lamp to be mounted on upper and lower parts to enable to cure both sides in one equipment. Therefore, it can be effectively used for the production of a variety of electronic parts as well as PCB coating (Conformal Coating).

▫ JHCI-102C-UD JECO UV curing machine is designed for each UV lamp to be mounted on upper and lower parts to enable to cure both sides in one equipment. Therefore, it can be effectively used for the production of a variety of electronic parts as well as PCB coating (Conformal Coating).

Currently in U.S.A, Japan, Europe, etc., Conformal Coating is broadly used for the purpose of waterproofing, damp proofing, electrical insulation, corrosion proofing of electrical product. As such, apart from the existing method of dip coating using urethane or silicone (Poor working environment), they positively introduce UV Conformal coating method for simplification of process and cost saving (Labor, Inventory, Material Waste Floor Space). Accordingly, in anticipation of change in the electronic product manufacturers, JECO has developed UV both-sided curing machine that minimizes the inefficiency such as working upper side and lower side separately in coating PCB or electronic product.

For lamp specification and structure change related with the product size, please consult with our Technical Department for customized production.

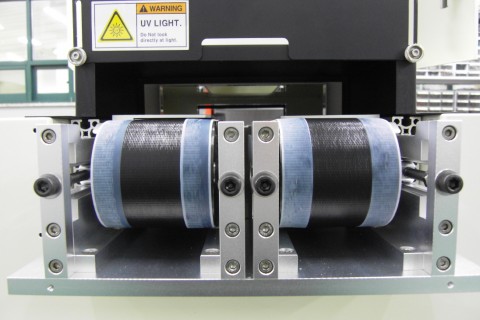

- UV curing machine that can simultaneously cure both sides of PCB and a variety of electronic parts.

- UV lamp is mounted on the upper and lower parts respectively, which enables to cure both sides simultaneously in single equipment.

- Both-side curing machine can shorten working process and working space.

- Both sides of product passes through UV curing zone with both sides of product placed on the belt.

- Buzzer sounds when it reaches lamp replacement time.

- Easy to manufacture a small-size product.

- Simple manipulation.

- Easy to replace conveyor belt.

- It provides an excellent maintenance because UV lamp can be easily replaced.

- Height of upper lamp house is freely and simply controlled owing to its handle attached.

- Height of lamp house can be adjusted with the lamp turned on

- Lamp height indicator is mounted being easy to refer to the height of lamp.

- Height of lamp for the lower lamp house can be adjusted to 3 steps.

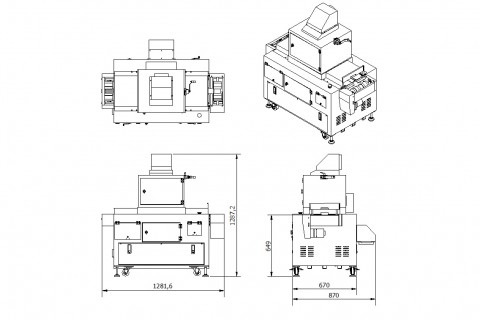

GENERAL SPECIFICATION

| ITEM | DESCRIPTION |

|---|---|

| SYSTEM DIMENSION | 1280 mm (L) x 670 mm (W) x1140mm (H) |

| CURING WIDTH | MAX 80 |

| INPUT VOLTAGE | 220V , 1 PHASE, 60Hz OR 50Hz |

| LAMP TYPE | MERCURY OR METAL UV LAMP– 2 EA |

| LAMP ARC LENGTH | 125mm |

| TOTAL CONSUMTION | 1 KW / LAMP |

| WAVELENGTH | 320 ~ 420 nm(Peak : 365nm) |

| IGNITION TIME | 3 MINUTE |

| REFLECTOR | COLD MIRROR |

| IR FILTER (152X152X2T) | 1EA(option) |

| MAIN SWITCH | MAIN POWER ON/OFF SWITCH |

| LAMP ON | LAMP ON SWITCH |

| LAMP OFF | LAMP OFF SWITCH |

| COLOR | STANDARD (IVORY) OR CUSTOM COLOR |