UV Lamp

METAL LAMP

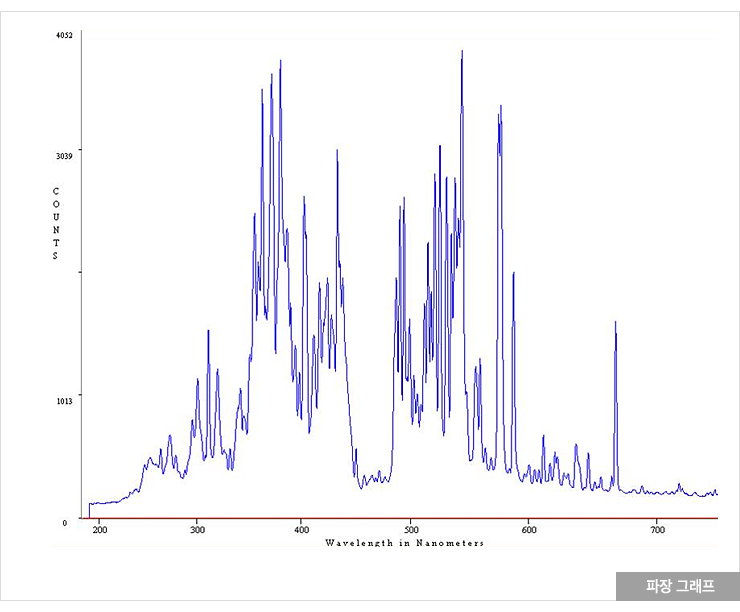

Since several abundant wavelengths are outputted in vicinity of 365mm, it has a better penetration than mercury lamps.

Feature

Feature– Most of UV resins are made for better hardening as higher the energy is.

– It has a higher long wavelength UV output of 300mm ~ 450mm than a mercury lamp.

– It has a higher long wavelength UV output of 300mm ~ 450mm than a mercury lamp.

SPECIFICATION

SPECIFICATION

Feature & Advantage

Feature & Advantage1. Most of UV resins are made for better hardening as higher the energy is.

2. Short wavelength UV has high energy but its penetration is not so good. Compared with it, the long wavelength UV has low energy but its penetration is so excellent that there are many incidents required for the thick coating liquid or for the colored coating.

3. AS mercury UV lamp has a disadvantage that only 365mm single spectrum outputs in the middle wavelength wave. To improve it, it is required for the lamp generating the middle wavelength wave. From this viewpoint, the lamp manufactured by using iron as an luminance material instead of mercury and by adding iron and metal admixtures such as tin is called “Metal Halide UV Lamp”.

4. It has a higher long wavelength UV output of 300mm ~ 450mm than a mercury lamp.

5. As several rich multiple wavelength waves output in vicinity of 365mm, it has a better penetration than mercury.

6. It is widely used for print boards, soldering masks, and UV inn drying.

2. Short wavelength UV has high energy but its penetration is not so good. Compared with it, the long wavelength UV has low energy but its penetration is so excellent that there are many incidents required for the thick coating liquid or for the colored coating.

3. AS mercury UV lamp has a disadvantage that only 365mm single spectrum outputs in the middle wavelength wave. To improve it, it is required for the lamp generating the middle wavelength wave. From this viewpoint, the lamp manufactured by using iron as an luminance material instead of mercury and by adding iron and metal admixtures such as tin is called “Metal Halide UV Lamp”.

4. It has a higher long wavelength UV output of 300mm ~ 450mm than a mercury lamp.

5. As several rich multiple wavelength waves output in vicinity of 365mm, it has a better penetration than mercury.

6. It is widely used for print boards, soldering masks, and UV inn drying.